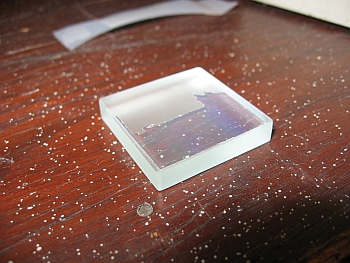

An old reflection grating

When John Crocker and I built the RAS solar spectroscope (see some of the spectra here), we had no budget for the project. We used what was available and free for us to use; so we used blue acrylic as the structural material of the spectroscope; razor blades for the slit; spare singlet convex lens for the collimator, a surplus finderscope as the viewing scope; and finally, we bought 3 "defective" surplus reflection gratings from Edmund Scientific. This was the special--they were defective in some manner, enough to fail some sort of specification, but not enough to be truly defective. You couldn't specify resolution or anything; so we bought three on the correct thought that one of them would likely match our specs.

Over the years the aluminum corroded and was giving a lot of scatter in the spectroscope; what this did was create a gray mush on top of the spectrum. So I endeavored to get the grating recoated.

Fluorescent light spectrum

Eventually, I discovered someone willing to use a coating machine on campus to recoat the grating. This meant I should prepare the grating for recoating, and I removed it from the spectroscope for a bath. Standard techniques for removing aluminum off of glass require something that will dissolve the metal but not hurt the glass surface. NaOH is out as it like many bases will etch glass. Instead a good acid is needed. Nitric is popular, but I did not have any. I thought about glacial acetic acid, since we have some as stop bath. But I realized I had hydrochloric acid, another excellent acid for this process. That source was toilet bowl cleaner. I had some already, instead of going to the hardware store for muriatic acid (an obsolete name for hydrochloric). A note: depending on your retailers, the muriatic acid at the hardware or pool store may be cheaper than toilet bowl cleaner. It is certainly a purer source.

A view of the oxidized old coating.

Smells fantastic, but don't breathe deeply. Acid fumes.

After a while I was concerned the metal was not coming off. A test piece of aluminum foil started dissolving in minutes, so I knew the problem was with the grating. Some old coatings can have such a thick aluminum oxide coating that the underlying metal is protected from the acid, and one trick is to damage the coating via a pinprick or scratch near the edge. I decided to try scotch tape--it can remove surfaces nicely.

A first pass pulled off half the aluminum coating, oxide and all. Success! I could see the grating underneath. But disaster struck on the second pass.

You see, I had assumed the grating was actually on the glass: a long repetition of grooved lines in the glass. Instead, it was a thin layer of plastic replica glued on top. The second pass with tape removed the grating, leaving me with a worthless piece of frosted glass. So much for a simple near-zero cost for repairing the spectroscope. But now I have wintergreen-smelling fresh glass squares.

No comments:

Post a Comment